About KEMPER

KEMPER WELDING FUMES EXTRACTION SYSTEMS:

KEMPER is the leading international Group specializing in Fume Extraction & Filtration Systems, Solar trackers, Industrial Automation and related services. We are present in more than 70 countries.

- Founded in 1977

- Group Business – Welding & Cutting, Solar Trackers, Industrial Automation.

- World Wide Group with1500 Employees.

- Presence in more than 70 countries.

- Existence in more than Development, production and distribution of extraction and filtration systems.

Fume Extraction - Why it is required ?

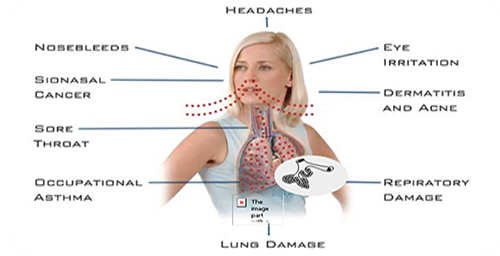

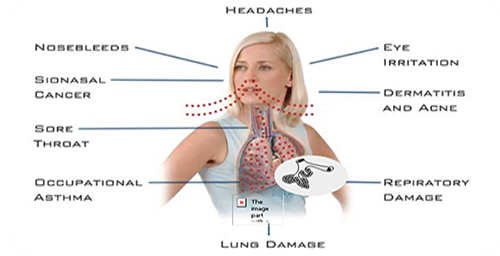

Hazardous smoke and pollutants are generated during welding and cutting in the metal industry. Using Kemper extraction and filtering equipment, we make sure that operators can still breathe in clean air. With an extensive range of health and safety equipment, we can provide protection against UV/IR radiation, heat, sparks and weld spatter, benefiting not only the operator but also the machinery and the environment.

- During welding or cutting process, superfine particles are generated.

- Size of a welding fume can as small as 0.1 micron to 1.0 micron - which can be easily exchange at the alveole and enters blood human stream.

- Over exposure can lead to long term & serious medical conditions such as Asthma, Headaches, Sore Throat, Lung Cancer etc.

Why Fume Extraction, is Essential

- It prevents from serious diseases such as Asthma, Lung cancer, Alzheimer's, Parkinsons etc .

- Reduced absenteeism, better working environment and improves employers relationship.

- Indirectly - increases productivity.

- Compliance to local and international EHS norms -COSHH,OSHA,NIOSHH or equivalent local regulations.

- To enhance the life of costly equipment and their efficiency

- To prevent expensive downtime.